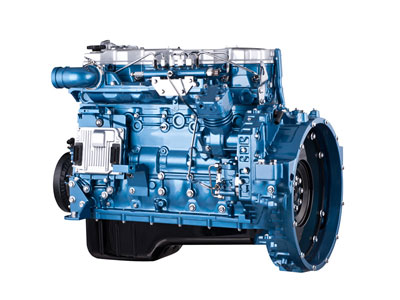

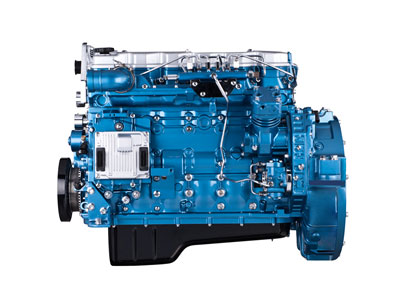

H Series Diesel Engine

SDEC's new H series engine is an energy-saving and environment-friendly engine professionally made by introducing a design concept from Europe and America, combining advanced four-valve technology, cracking connecting rod, lightweight manufacturing process, etc. It completely meets the National IV and the future National V Emission Standard. This engine fully integrates today's worldwide cutting-edge technologies of internal-combustion engines with such advantages as fuel efficiency, strong power, good reliability and low noise, making it the ideal power for large and medium size passenger cars.

Diesel Engine SC7H

Power Range: 180~260PS

| Model | Unit | EuroIII/IV |

|||||||

| SC4H 180 Q4 |

SC4H 200 Q4 |

SC4H 215 Q4 |

SC4H 220 Q4 |

SC4H 230 Q4 |

SC4H 245 Q4 |

SC4H 260 Q4 |

|||

| Type | |

|

|||||||

| Aspiration | mm×mm | TCI | |||||||

| Bore×Stroke | L | 105×124 | |||||||

| Total Displacement | |

6.5 | |||||||

| Rated Power/Rated Speed | kW/r/min | 132/ 2300 |

147/ 2300 |

158/ 2200 |

162/ 2500 |

170/ 2300 |

180/ 2300 |

192/ 2300 |

|

| Mini Fuel Consumption | g/Kw.h | ≦190 | |||||||

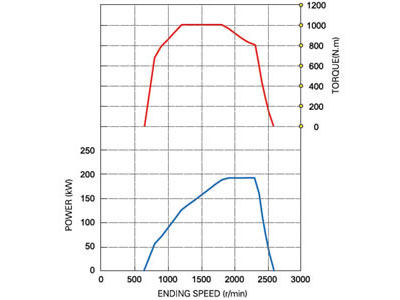

| Maximum Torque/Speed | N.m/r/min | 600/ 1200~ 1600 |

750/ 1200~ 1600 |

900/ 1200~ 1600 |

800/ 1200~ 1600 |

900/ 1200~ 1600 |

960/ 1200~ 1600 |

1000/ 1200~ 1800 |

|

| Noise | dB(A) | ≦95 | |||||||

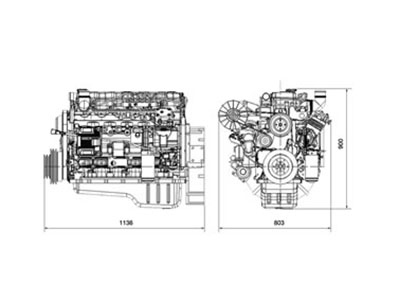

| Overall Dimension | mm | Length: 1136 Wide: 725 High: 900 | |||||||

| Weight | kg | 480 | |||||||

Technology adopted: four valves per cylinder and the fuel injector is arranged vertically right in the center;

Function: increased inlet airflow and better rationalize atomized fuel distribution;

Advantage: improved engine power (horsepower and torque) and decreased engine fuel consumption.

Technology adopted: Nippon Denso's latest generation of HP3 high-pressure common rail fuel system;

Function: maximum fuel-injection pressure reaches 1800bar, the effect of fuel atomization is better, and the flow deviation of the fuel injector is controllable;

Advantage: lower engine emission, noise and fuel consumption.

Applied technologies: modular integration design integrating the engine oil cooler chamber, water pump volute casing, engine-oil pump chamber, etc. on the engine body;

Function: decreased number of engine parts and sealing surface; Advantage; improved reliability.

Applied technologies: integral cylinder cover;

Function: good rigidity of the whole engine;

Advantage: lower vibration and noise.

Applied technologies: patented design of engine body with strengthening rib, high stiffness and high strength;

Function: good rigidity of the whole engine;

Advantage: lower vibration and noise.

Applied technologies: cracking connecting rod;

Function: one-to-one matching of upper and lower covers for connecting rod, preventing mistake and with good alignment;

Advantage: easy repair and maintenance.

Applied technologies: dry-type cylinder liner;

Function: the cylinder sleeve material performs better than the engine body material;

Advantage: improved wearing resistance capacity; repair and maintenance easier than that without cylinder sleeve.

Applied technologies: piston with all-aluminum wavy inner-cooling oil passage;

Function: improved cooling effect of the piston;

Advantage: improved operation reliability of the piston.

Applied technologies: Nippon Denso's world-leading ceramic chip ECU;

Function: small heat dissipation amount requires no external connection of cooling pipeline;

Advantage: high reliability of the entire engine.

Applied technologies: Japanese double-layer material used in the high-pressure oil pipe;

Function: higher pressure-proof and corrosion-resistant capacity;

Advantage: high reliability of the fuel pipeline.

Applied technologies: standardized design of peripheral accessories;

Function: exchangeable with mainstream accessories;

Advantage: easy repair and maintenance.

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی