Truck Natural Gas Engine

The truck natural gas engine is commonly mounted in the middle and heavy duty vehicles that utilize the compressed natural gas (CNG) or the liquefied natural gas (LNG), conforming to the emission standard of China V. As it adopts the imported gas appliances that are made with advanced technology and reliable quality in mass production, this product realizes the single point injection in front of the throttle valve to ensure the fuel is mixed with the air totally and the fuel in each cylinder burns stably and smoothly.

This truck natural gas engine makes use of the electronically controlled units to get all the operating parameters to control the gas injection amount precisely. Moreover, it will correct the air fuel ratio in a closed loop according to the measured value of the universal exhaust gas oxygen (UEGO) sensor. As the suitable power support for the public buses, intercity coaches and regional transport trucks, this product is adequate to fulfill the requirements of abovementioned vehicles, such as high performance, low pollution and noise.

SC9DT Natural Gas Engine

| Model | Unit | EURO III, Euro III/Euro IV/Euro V | |

| SC9DT280 | SC9DT320 | ||

| Type | In-line, electronically controlled, TCI, 4-stroke, water cooling | ||

| Bore ×Stroke | mm | 114×144 | |

| Total displacement | L | 8.8 | |

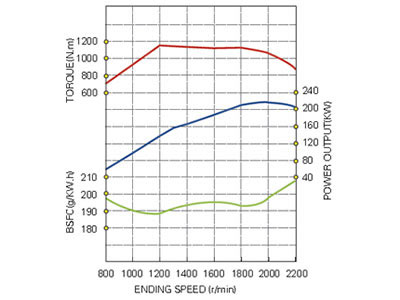

| Rated power/rated speed | kw/r/min | 206/2200 | 235/2200 |

| Maximum torque/speed | N.m/r/min | 1120/1400 | 1250/1400 |

| Min. fuel consumption | g/kw.h | ≤215 | |

| Noise | dB(A) | ≤96 | |

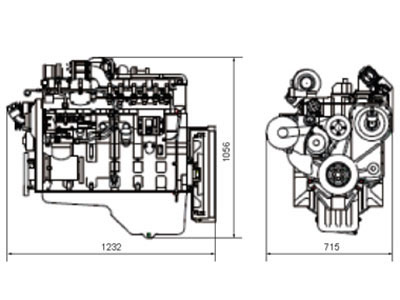

| Overall dimension | mm | Length: 1345, Width: 715, Height: 1075 | |

| Net weight | kg | 760 | |

| Power range | ps | 280~320 | |

Function

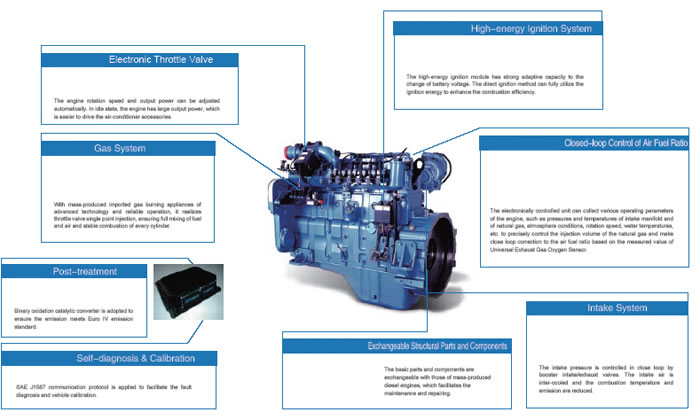

1.Electronic Throttle Valve

The rotary speed and the output power of the truck natural gas engine is regulated by the electronic throttle valve automatically. When the engine works with large output power at idling, it is easier to drive the accessories of the air conditioner.

2. Gas System

Made in mass production, this imported gas system is reliable and advanced. With the single point injection technology in front of the throttle valve, this system gets the fuel and the air fully mixed and the fuel in every cylinder burned smoothly.

3. Post treatment

The binary oxidation catalytic converter is applied so that the emission of the product is consistent with the Euro IV standard.

4. Self-diagnosis and Calibration

Through the SAE J1587 communication protocol, this truck natural gas engine facilitates the fault diagnosis and calibration for the vehicle.

5. High Energy Ignition System

The high energy ignition module owns excellent capacity to adapt to the change of the battery voltage. With the direct ignition method, this system is able to make full use of the energy for ignition, increasing the fuel efficiency.

6. Control on Air Fuel Ratio in Closed Loop

The electronically controlled unit works on the operating parameters, such as the pressure, temperature of intake manifold and the natural gas, atmosphere conditions, rotary speed, water temperature, etc. It is commonly used to control the injection volume of the natural gas accurately. On the basis of the measured value of the UEGO sensor, the unit will correct the air fuel ratio in the closed loop.

7. Exchangeable Structural Parts and Components

The essential components and parts of the truck natural gas engine are exchangeable with those of other diesel engines in mass production and they are easy for maintenance and repair.

8. Intake System

The intake pressure is controlled in the close loop by means of pressurizing the intake or exhaust valves. Through the inner cooler, the intake air will be cooled to realize the reduction of the combustion temperature and emission.

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی