Truck EGR (Exhaust Gas Recirculation) Engine

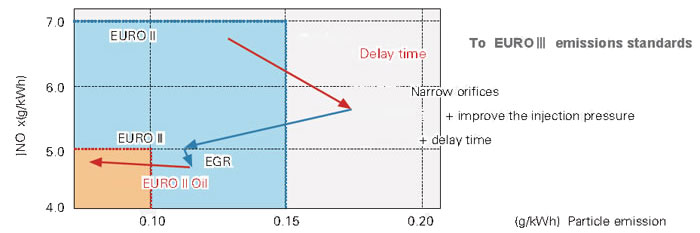

EGR, commonly known as an exhaust gas recirculation system, is the purification device for the nitrogen oxides NOx that is one of the hazardous gases exhausted by the engine. Due to this system, a small amount of exhaust gas generated by the truck EGR engine will go back to the cylinder to delay the combustion process. The total flow of exhaust gas is decreased so that the nitrogen oxides are reduced in the end. Then the emission standard is improved.

SC10E (EGR) Exhaust Gas Recirculation Engine

| Model | Unit | EURO III, Euro III/Euro IV/Euro V | ||||

| SC10E290Q3B | SC10E310Q3B | SC10E340Q3B | SC10E380Q3B | SC10E420Q3B | ||

| Type | In-line, mechanical pump, embedded EGR, TCI, water cooling wet cylinder liner, rear gear housing | |||||

| Bore ×Stroke | mm | 128×135 | ||||

| Total displacement | L | 10.4 | ||||

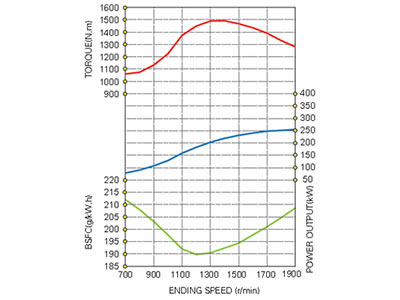

| Rated power/rated speed | kw/r/min | 213/1900 | 228/1900 | 250/1900 | 280/1900 | 309/1900 |

| Maximum torque/speed | N.m/r/min | 1190/1400 | 1350/1400 | 1450/1400 | 1600/1400 | 1800/1400 |

| Min. fuel consumption | g/kw.h | ≤190 | ||||

| Noise | dB(A) | ≤97 | ||||

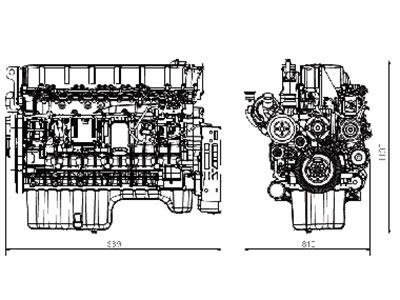

| Overall dimension | mm | Length: 1389, Width: 810, Height: 1130 | ||||

| Net weight | kg | 980 | ||||

| Power range | ps | 290~420 | ||||

| Built-in EGR | Reduce Nox |

| Delayed injection timing | Reduce Nox |

| PZ-8500 pump for improving the injection pressure (140MPa) | Reduce particles |

| Narrowed orifices | Reduce particles |

| Diesel in accordance with China III standard | Reduce particles |

Product Features

1.Low Cost

This truck EGR engine gets some slight changes based on the China II emission standard. The versatility rate of its parts exceeds 95%. The fuel injection system is similar to the inline pump that is consistent with the China II standard, not sensitive to the fuel products.

2. Low Fuel Consumption

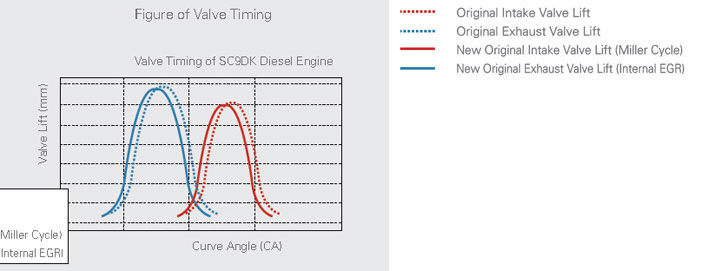

There are 7 small orifices for fuel injection with high flow rate ranging from 1200 to 1400ml/min. This product gets the fuel atomized thoroughly and optimizes the timing performance of the intake valve. At the later stage of the intake stroke, the valve will be closed for getting the air in the cylinder expanded to reduce the temperature of the inner air properly, as well as the maximum combustion temperature. This is the working process of Miller Cycle Theory.

Through the EGR system in the cylinder, the inert gas is increased in the cylinder to inhibit the generation of NOx. Due to the inner EGR and Miller Cycle technology, the flow rate of the intake air is reduced, the combustion at low air fuel ratio comes true and the emission is decreased successfully.

3. Low Maintenance Cost

This truck EGR engine is same as the diesel engine of China II standard in several aspects, such as the operation, repair and maintenance.

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی